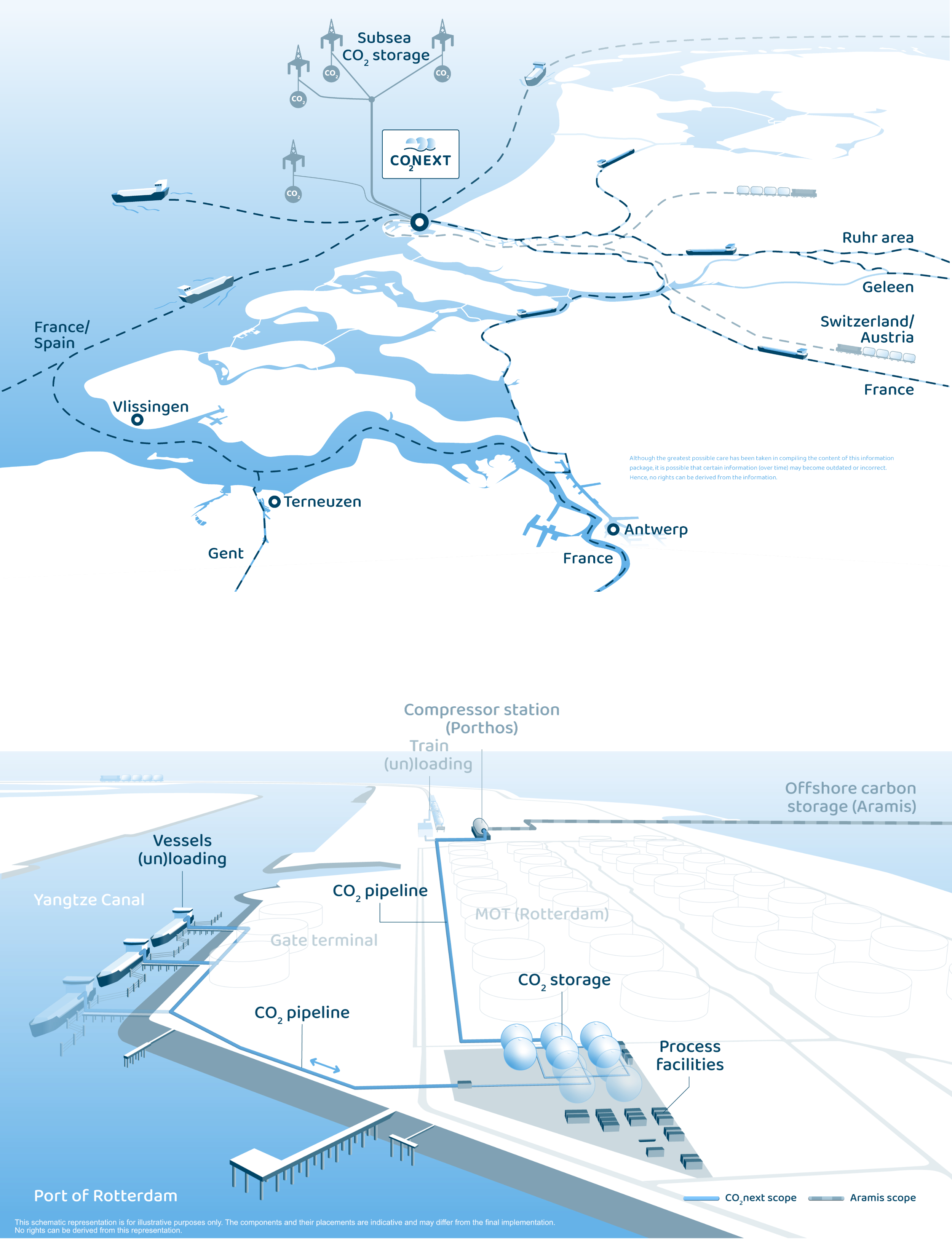

To achieve the targets set out in the Dutch Climate Agreement and the European Green Deal, CO2 emissions must be significantly reduced. One of the ways to accomplish this in the short term is by capturing and storing CO2 emitted by industry. This process is known as Carbon Capture and Storage, or CCS. In the Netherlands, new CO2 infrastructure is being developed for this purpose. CO2 captured by industry can be transported via pipeline or vessel to the Maasvlakte and from there via an offshore pipeline to the North Sea. In the North Sea, CO2 can be stored in depleted gas fields beneath the seabed through injection platforms. CO2next is being developed for industries not easily connected to a CO2 pipeline but still wishing to utilize this storage.

Open access terminal

CO2next is exploring the construction of an independent, open-access terminal for liquid CO2 at the Maasvlakte in the Port of Rotterdam. From this terminal, CO2 can be stored in depleted gas fields beneath the seabed (CCS), for example, via the infrastructure of the Aramis initiative. The terminal can receive CO2 delivered by ships and—potentially – in future by rail. This allows all CO2-emitting industries to access storage beneath the North Sea, even those not connected to an onshore CO2 pipeline. Additionally, we aim to facilitate the onward transportation of CO2 from the terminal for future reuse (CCU), contributing to circular solutions for industrial emissions.

Multi-customer

- CO2next will operate as a non-discriminatory, multi-customer terminal, open to all companies, whether based in the Netherlands or abroad.

- Since unveiling our plans during an “open season” in 2021, we have engaged with a wide range of customers.

- CO2next is particularly appealing to companies interested in CCS beneath the North Sea but not connected to an onshore CO2 pipeline to transport their captured CO2 to the Maasvlakte.

Capacity

- At launch, the terminal will have the capacity to handle approx. 5.4 million tons per year (Mtpa).

- In the first growth phase capacity will increase to approx. 10 Mtpa.

- Depending on market demand and the development of CCS chains, the terminal could grow to handle approx. 15 Mtpa.

The terminal

The terminal will have several key features:

- 2 (growth phase: 3) jetties where ships can deliver liquid CO2.

- A CO2 pipeline from the jetties to the storage tanks.

- 6 (growth phase: 8) spherical tanks for temporary storage of CO2.

- Process facilities to maintain the CO2 at the correct pressure.

- A CO2 pipeline from the storage tanks to the offshore pipeline.

More information

The terminal is planned for the Maasvlakte in Rotterdam, Netherlands, along the Yangtze Canal. This strategic location offers excellent accessibility by ship, both by river and by sea, and is in close proximity to sea pipelines leading to the depleted gas fields. In the future it will probably also be possible to reach the terminal by train.

We are targeting a final investment decision in 2026/2027. If everything goes as planned, the terminal could be ready to start up in 2029/2030.

The development of CO2next takes place in a public-private partnership between Gasunie, Vopak, TotalEnergies and Shell. The partners are working together to ensure the safe storage and handling of CO2 with their extensive technical expertise, experience and knowledge.

Vopak offers crucial infrastructure for indispensable energy sources and raw materials through storage and transshipment. Gasunie provides safe, reliable and sustainable infrastructure for large-scale transport and storage of gases. Shell and TotalEnergies are global leaders in carbon capture and storage. They are also partners in the Northern Lights project, which built the first facility for the import of liquid CO2 in Europe.

While CCS is new to the Netherlands, it has been successfully implemented elsewhere in the world for over 20 years. In Norway, the Sleipner and Snøhvit projects have stored more than 20 million tons of CO2 beneath the North Sea seabed. Similar projects, such as Quest in Canada and Illinois Industrial in the United States, have been storing CO2 for years. Globally, around 20 facilities are currently operational.

Safety is paramount in every aspect of the project. Before construction can begin, all components of the plan will be reviewed by authorities responsible for granting permits. All parts of the terminal are designed in such a way that the highest safety standards are achieved. Once the terminal is operational, management systems will ensure that unwanted situations are prevented. While we adhere to strict safety standards during both construction and operation, it is important to note that CO2 itself is not a hazardous substance.

CO2 is inherently low-risk and naturally present in the air. It is non-flammable, does not easily react with other substances, and is even used as a fire suppressant.

CO2 poses a risk only in very high concentrations to humans and animals. In extremely rare scenarios where large amounts might be released, there could be a risk to the immediate vicinity, such as personnel present at the terminal. However, through the use of carefully selected materials, construction methods, and safety systems, the likelihood of a significant leak is minimal.

CO2 detectors will be installed at multiple locations throughout the terminal. In the unlikely event of a CO2 release, clear protocols will be in place to manage the situation. To ensure effective responses these will be coordinated with the Safety Region and emergency services.

We want to build a terminal with as little impact as possible on nature and the environment. An Environmental Impact Report (EIR) has been drawn up which indicates the expected impact and what measures we must take to limit these consequences. Some of the measures are that the ships that bring CO2 sail electrically as much as possible and use shore power at the jetty. To limit noise (above and below water), we use the quietest possible working methods during construction (especially for piling work on scaffolding) and we ensure that installations that produce the most noise are installed indoors. A summary of the EIR (in Dutch) can be found via this link.

We value good relationships with all our stakeholders. We believe it is important to engage in dialogue with our environment and to inform all stakeholders in a timely manner about relevant matters. Naturally, we are also happy to discuss any questions or concerns you may have.

For more information about participation and the permit process, please look here.

If you are interested in the options for supplying CO2, please look here.

Do you have a question?

Please fill out this contact form. We will then contact you as soon as possible.